20

Apr

20

Apr

Holiday Inn-H4 manufactuered by rainbow work team ,we have strict quality control for every step from design to production process.

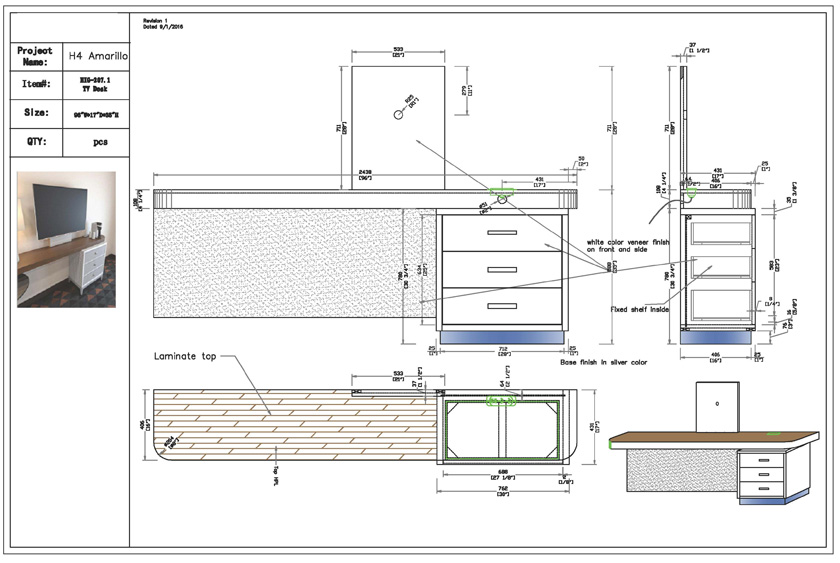

Our CAD guys will make CAD shop drawing first follow IHG group specifications ,after we got approved shop drawing we will ask factory make one pcs PPS for each item ,then our QC can check the whitewood materials (MDF ,HPL ,solidwood etc.) then can test the size if match our approved shop drawing also check the structure is strong enough or not.

After QC checked the whitewood PPS ,our project manager will send the QC report to our clients ,then if have any questions we can improved at the begining.

Then factory will make painting PPS follow approved stained sample ,then we will still send QC report to clients then they can know our schedule .

During the mass production ,our QC will 100% inspect follow our QC stands. Our QC have 20 years professonial experience on hotel furniture ,we believe our lovery team can help client fished their project perfectly.

Attached some photoes for your reference they you can know our work process ,if you have any needs about your hotel project please feel free contact rainbow team .